In-process quality checks and pre-dispatch inspection are keys to ensure high quality deliverables. Having right quality measuring instruments with a good knowledge on how to use them effectively is therefore essential for Quality control.

In this blog, I would like to explain various quality measuring instruments we use at Advent.

Fix Bed Cmm Machine

Key Function

A Coordinate Measuring Machine (CMM) is a device that measures the geometry of physical objects by sensing discrete points on the surface of the object with a probe.

- • Advent has Accurate Coordimeasure Bridge type CMM machine which has:

- X -1000mm (width)

- Y-2000mm (length)

- Z-800 mm (height)

- Accuracy-Permissible measuring uncertainty is in microns and the repeatability is 0.002 microns.

- The Fix Bed CMM machine is used for 2D inspection, 3D profile comparison for CF & parts with high accuracy.

Romer Absolute Arm & Scanner CMM Machine

Key Function

The Romer Absolute Arm is a portable 7-axis coordinate measuring machine (CMM). It has the ability to accurately measure features on parts using a ruby touch probe or a laser scanner. Together, the touch probe and the scanner make the Romer Absolute Arm an extremely powerful measuring device.

- Advent has 2 Romer Absolute Arm machines & one Romer-plus-Scanner CMM machine .

- The Romer CMM machine is portable which is used for part checking - 2D & 3D inspection, 3D profile comparison of checking fixtures and the Scanner CMM machine is also used for Reverse Engineering.

Vernier Calipers

There are 4 types of VCs:

- Digital VC

- Mechanical VC

- Dial VC

- Depth Vernier

Key Function

A Vernier caliper is used to measure the Internal & External diameters of an object. It can also be used for depth measurements with the employment of a probe that is attached to the movable head.

- Advent has all these four types of vernier calipers in different ranges.

- They are used to measure the pin bush diameters of checking fixtures and Automobile components.

- Vernier caliper is used in a die assembly to measure the depth, height, diameter etc.

Bore Gauges Sizes

Key Function

A Bore Gauge is used to measure the inside diameter of a hole or cylinder. Bore gauges are used in applications where holes, cylinders, and pipes need the be measured, such as automotive, manufacturing, and inspection and calibration uses.

- Advent has bore gauges with various size ranges, i.e., size-6-10mm, 10-18mm,18-35mm and 50-150mm.

- Bore gauges are used to measure the bush ID of checking fixtures, Automobile & Aerospace parts.

- It is also used in tool to measure the Hole ID in die block assemblies, blanking and piercing tools.

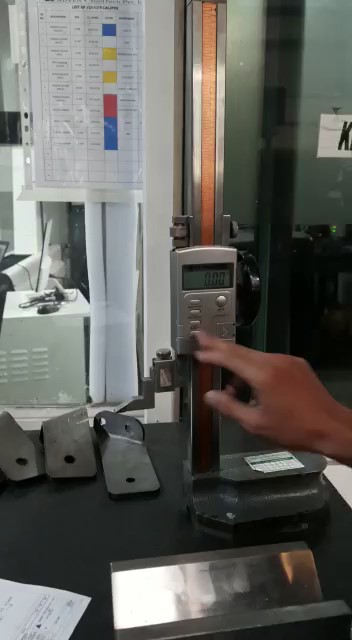

Digital Height Gauge

Key Function

Height gauges can be used to determine an object or work piece's height with extremely high accuracy and precision.

- Advent has a Digital Height gauge of range 0 to 300mm .

- Center-line distances, internal/external diameters, and step heights are some of the different measuring tasks that can be carried out by high-specification digital height gauges.

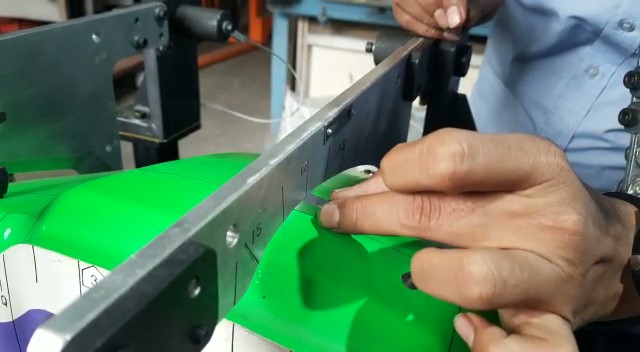

Slip Gauge

Key Function

Slip gauges or gauge blocks are used as standards for precision length measurement. These gauges are made in sets and consist of a number of hardened blocks made of high-grade steel with low thermal expansion.

- As shown in the video, slip gauges are used for Template gap checking in Checking fixtures.

- This is also used in VMC machine operations for setting.

Micrometers

Key Function

Micrometers are specially designed for the measurement of very small objects. They allow for the highly precise measurement of any item that fits between the anvil and spindle.

- Advent has micrometers with different size ranges .i.e. size 0-25mm 0-50 mm , 50-75mm, 75-100mm, 100-125mm, 125-150 mm & 175-200mm .

- Micrometers are used to measure the guiding diameter of pins for checking fixtures.

- Point micrometers are used for measuring the thickness of the development parts for thinning checks.

Go-Nogo Gauges

Key Function

A Go/No-go gauge refers to an inspection tool used to check a workpiece against its allowed tolerances via a go/no-go test.

- Advent has Go-Nogo Gauges - the Round & D-shape gauges in sizes of Ø4H7, Ø5H7, Ø6H7, Ø8H7, Ø10H7 & Ø12H7 etc.

- This standard Go-Nogo Gauges are used for Bush inspection of CF.

Leave a Reply